When deciding between OEM (Original Equipment Manufacturer) and generic parts for inflatables, the choice boils down to cost versus reliability. OEM parts are specifically designed to match the exact specifications of your inflatable, ensuring safety, durability, and performance. They cost 30-60% more but last longer, maintain warranties, and reduce the risk of failures during use. Generic parts, while 30-50% cheaper, often compromise on fit, quality, and lifespan, making them suitable only for non-critical repairs or older equipment.

Key Takeaways:

- OEM Parts: Higher cost, perfect fit, longer lifespan, safety-focused, warranty-friendly.

- Generic Parts: Lower cost, universal fit, shorter lifespan, limited warranties, potential risks.

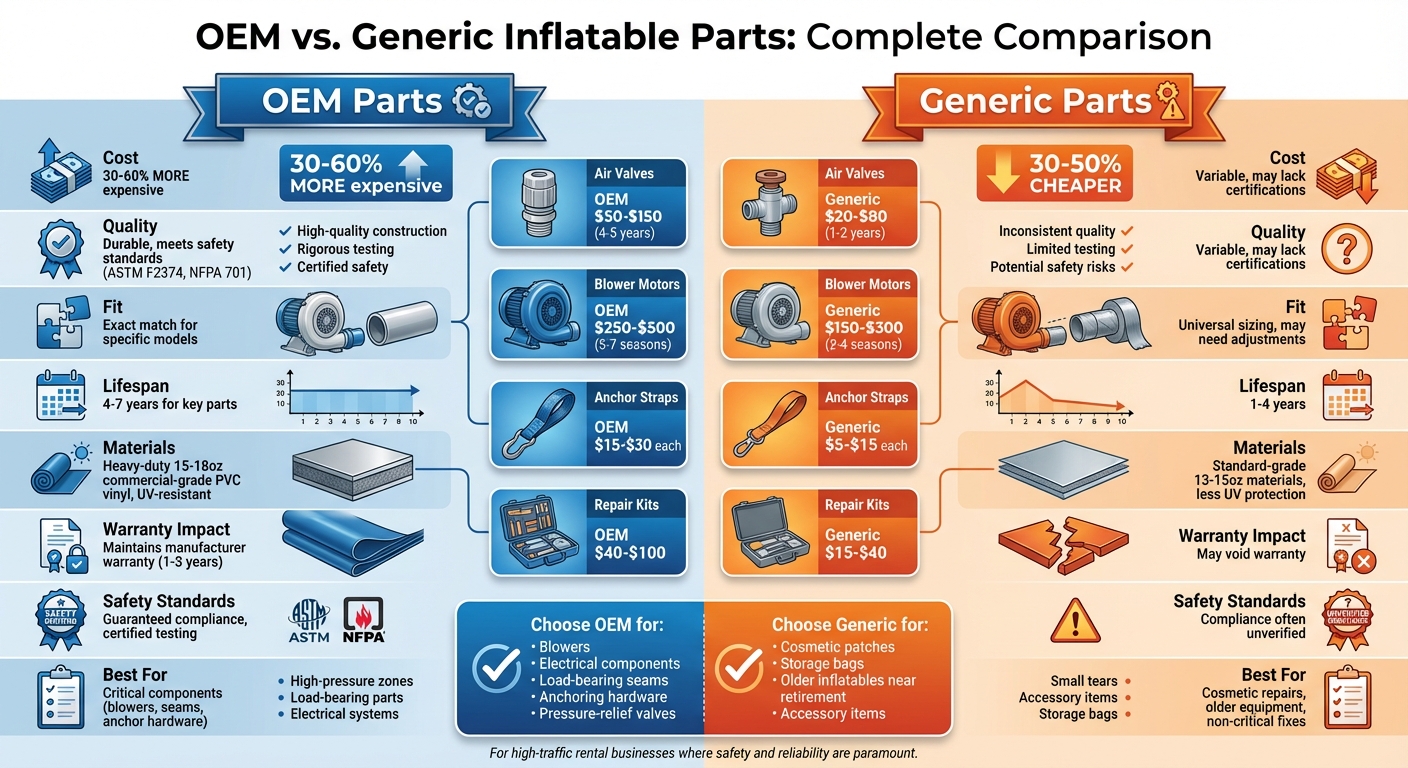

Quick Comparison:

| Factor | OEM Parts | Generic Parts |

|---|---|---|

| Cost | Higher (30-60% more expensive) | Lower (30-50% savings) |

| Quality | Durable, meets safety standards | Variable, may lack certifications |

| Fit | Exact match for specific models | Universal, may need adjustments |

| Lifespan | Longer (4-7 years for key parts) | Shorter (1-4 years) |

| Warranty Impact | Maintains unit warranty | May void warranty |

For critical components like blowers, seams, and anchor hardware, OEM parts are the safer choice. Generic parts work for minor, cosmetic fixes or older inflatables nearing retirement. Choose wisely to balance upfront costs with long-term reliability and safety.

OEM vs Generic Inflatable Parts Comparison Chart

What Are OEM Inflatable Parts?

OEM inflatable parts are components made by the same company that originally manufactured your bounce house, water slide, or obstacle course – or by an authorized partner following their exact specifications. Essentially, they’re the "genuine" parts tailored specifically for your inflatable’s brand and model, whether it’s from Magic Jump, Ninja Jump, Blast Zone, or another original manufacturer. This precise match ensures consistent performance and safety.

These parts aren’t one-size-fits-all. For instance, an OEM blower is engineered to provide the exact airflow and pressure required to keep a specific model properly inflated, even under heavy use. Similarly, valves, anchor points, and repair panels are designed to align perfectly with the original specifications of your inflatable. This level of precision is essential to avoid breakdowns or failures.

What sets OEM parts apart is the high manufacturing standards they adhere to. Most are built using tough, UV-resistant materials that match what was used in the original construction of the inflatable.

Key Features of OEM Parts

OEM parts stand out for their precise fit, durable materials, and added warranty protection. Since these parts are crafted from the original design blueprints, they align perfectly with the inflatable’s stress points, seam locations, and airflow needs. They’re made with heavy-duty, UV-resistant materials, reinforced stitching, and load ratings that meet industry safety standards, such as ASTM F2374 for inflatables and amusement rides.

Many OEM parts also come with their own warranty, often covering up to 12 months, especially when installed by authorized technicians. This can also help maintain the manufacturer’s warranty on your inflatable.

Examples of OEM Inflatable Parts

A few examples of OEM parts include air blowers tailored to specific models, which ensure the right pressure and airflow during use. Model-specific valves are another example; they create airtight seals at connection points to prevent leaks. Repair patches made from matching UV-resistant vinyl are designed to restore the original strength and appearance of damaged areas.

Other examples include branded anchor point hardware, zipper assemblies for entry and exit points, and structural panels for high-wear areas like slide landings or obstacle course walls. For businesses like Bouncy Rentals USA, which manages a fleet of inflatables, having OEM parts on hand for these critical components helps reduce downtime and maintain top safety standards across their equipment.

What Are Generic Inflatable Parts?

Generic inflatable parts are third-party components designed to fit a variety of inflatable models. Unlike OEM (Original Equipment Manufacturer) parts, they lack the specialized engineering and precise tailoring specific to a particular brand or product. This trade-off between affordability and precision raises questions about their advantages and drawbacks.

One key difference is cost: generic parts are typically 30%-50% cheaper than OEM components. This price reduction is achieved by using standard-grade materials instead of high-specification, UV-treated vinyl or stitching that undergoes rigorous testing.

Another benefit is their broad availability. Generic parts are widely distributed, making them a go-to option during busy rental seasons when quick replacements are needed to keep operations running smoothly, as seen with companies like Bouncy Rentals USA.

Advantages of Generic Parts

Generic parts offer clear cost savings, especially for routine repairs or maintenance. Spending 30%-50% less on items like replacement blowers or valves can significantly impact the bottom line. For non-critical fixes where exact specifications aren’t crucial for safety, these parts are a practical solution.

Their widespread availability is another plus. Unlike OEM parts, which may come from a single distributor with limited stock, generic parts are produced by multiple suppliers. This means you can often find what you need locally or have it shipped quickly, reducing downtime. For example, sourcing a standard air blower or repair patch can take days rather than weeks, ensuring your rentals stay operational.

Generic parts are also a practical choice for older inflatables, especially when OEM support is no longer available. For instance, repairing a five-year-old obstacle course with a budget-friendly patch can extend its use for another season without the higher expense of OEM materials.

Limitations of Generic Parts

While cheaper, generic parts often come with compromises in quality and durability. Materials like thinner vinyl, lower-denier mesh, and less robust stitching can make these parts less durable and potentially less safe. Their universal design might not perfectly match your inflatable’s specifications, which could affect performance or even void warranties for newer models.

Another drawback is their shorter lifespan. Generic parts, made with standard-grade materials and mass-production processes, tend to wear out faster. This is especially true in the demanding world of party rentals, where inflatables face frequent setup, takedown, and heavy use by kids. What initially seems like a cost-saving option might end up being more expensive in the long run if replacements are needed repeatedly.

OEM vs. Generic Parts: Side-by-Side Comparison

Comparison Table: OEM vs. Generic Parts

Choosing between OEM and generic parts goes beyond just looking at the price tag. Here’s how they compare across key factors important for rental businesses:

| Factor | OEM Parts | Generic Parts |

|---|---|---|

| Initial Cost | Higher (60% more expensive) | Lower (30-50% savings) |

| Quality Assurance | Meets ASTM F2374 and NFPA 701 standards; certified testing | Variable quality; often lacks certified testing |

| Compatibility | Perfect fit; engineered for specific model dimensions | Universal sizing; may require adapters or modifications |

| Durability | Long-term; designed for commercial rental cycles | Short-to-medium term; faster wear under heavy use |

| Warranty Coverage | Maintains manufacturer warranty (typically 1-3 years) | Limited or no warranty; may void existing coverage |

| Safety Standards | Guaranteed compliance with fire retardancy and load-bearing specs | Compliance often unverified or missing |

Breaking Down the Comparison Factors

Let’s take a closer look at what these differences mean in practice.

Cost is the most obvious distinction. Generic parts can save 30–50% upfront, but those savings often come with compromises.

Quality and safety are non-negotiable for high-traffic rentals. OEM parts, made with heavy-duty, fire-retardant materials like 15oz to 18oz commercial-grade PVC vinyl, are built to handle constant use while meeting NFPA 701 fire safety standards. Generic parts, often made with lighter materials (13oz to 15oz), may not meet these safety benchmarks. For companies like Bouncy Rentals USA, where inflatables endure hours of jumping and sliding, the durability and safety of OEM parts are essential to avoid accidents and maintain reliability.

Compatibility is another critical factor. OEM parts are designed to fit specific models perfectly, making them easy to install without adjustments. Generic parts, on the other hand, rely on universal sizing, which can lead to air leaks or require time-consuming modifications like adding adapters for blower tubes. In the fast-paced world of event rentals, these delays can disrupt tight schedules and create unnecessary headaches.

Warranty coverage is a major consideration. Using generic parts often voids the manufacturer’s warranty on the entire inflatable unit. This leaves businesses unprotected if a significant failure occurs. Additionally, some insurance providers now require proof of OEM or equivalent-certified parts to maintain liability coverage. Skimping on OEM parts could result in denied claims, a risk that far outweighs the upfront cost savings.

This detailed breakdown highlights the trade-offs between cost and long-term value, setting the stage for a deeper dive into financial implications in the next section.

Cost Differences and Long-Term Value

Price Ranges for Common Parts

When comparing prices between OEM (Original Equipment Manufacturer) and generic inflatable parts, the difference is hard to ignore. For example, OEM air valves typically range from $50 to $150 each, while generic versions cost around $20 to $80 for similar sizes. Blower motors from OEMs are priced between $250 and $500, whereas generic models with comparable horsepower fall between $150 and $300. Even smaller components like anchor straps and D-rings show a noticeable gap: OEM strap assemblies cost about $15 to $30 each, while bulk-purchased generic kits cost $5 to $15 per point. As for repair kits, professional-grade OEM options are priced at $40 to $100, compared to $15 to $40 for generic PVC patch kits.

While fleet size impacts total parts expenses, spending more upfront on OEM parts often proves worthwhile by reducing downtime and minimizing emergency repairs.

Durability and Lifespan Considerations

Initial cost is only part of the equation – durability and lifespan reveal the true value of a part over time. Take air valves, for instance: OEM valves typically last 4–5 years, while generic versions only last about 1–2 years. This breaks down to an annual cost of $25–$30 for an OEM valve versus $15–$40 for a generic one. Similarly, OEM blowers, which can reliably operate for 5–7 rental seasons, deliver a lower cost per hour of use compared to generic blowers that may require replacement or major repairs after just 2–4 seasons.

When factoring in labor, shipping, and downtime, OEM parts often come out ahead for critical components. A single canceled event due to equipment failure can lead to hundreds of dollars in lost revenue, not to mention potential refunds and damage to your reputation. For high-demand businesses like Bouncy Rentals USA, where inflatables are rented several times a week during peak season, even a handful of failures from lower-quality generic parts can erase any savings and hurt overall profitability. Fleets with heavy usage benefit significantly from the reliability of OEM parts, as the cost of taking a popular inflatable out of service often outweighs the initial savings of cheaper alternatives.

Safety and Compatibility for Party Rentals

Safety Standards and Material Quality

When it comes to party rentals, safety isn’t just a priority – it’s a responsibility. The quality and compatibility of every inflatable part reflect directly on your reputation and liability. OEM parts are specifically designed to meet ASTM F2374, the U.S. standard for inflatable amusement devices, as well as state regulations that follow these guidelines. Many of these components also carry UL or ETL certifications and are flame-resistant. In contrast, generic parts, especially cheaper imports, often lack the necessary documentation to confirm compliance. This makes it challenging for both you and safety inspectors to ensure they meet required safety standards.

OEM parts are crafted from high-grade materials like UV-resistant PVC, vinyl, or Hypalon, which are built to withstand intense sunlight and repeated use. Generic parts, however, may skip these protective treatments, leading to brittleness, cracking, or even bursting under stress. In high-demand rental settings – like school events, block parties, or family gatherings – a single weak or poorly fitting component can fail, potentially causing deflation, trips, falls, or even entrapment hazards.

Fitment Challenges with Generic Parts

Material quality is only part of the equation. Proper fit is just as critical for ensuring safety. Generic parts often introduce small mismatches that can lead to big problems. For example, air tubes or blower cuffs that are slightly off in size may require over-tightening or taping, which can loosen during use. Similarly, anchor points or tie-downs that don’t match the original design may force operators to use fewer stakes or improper anchoring methods, compromising wind stability.

What’s especially concerning is that these fitment issues often go unnoticed until the inflatable is in use – when it’s packed with excited kids. Each workaround to make a generic part fit increases the chance of improper installation, turning minor gaps into serious hazards during events. Relying on parts with predictable performance and documented specifications is essential for protecting your business, particularly given the strict liability exposure and insurance requirements in the U.S.. These safety and fitment considerations emphasize why using precise, model-specific parts is not just smart – it’s necessary for any rental operation.

When to Choose OEM Over Generic Parts

Critical Components That Need OEM Parts

When it comes to blowers and electrical components, sticking with OEM parts is a must. These parts are responsible for managing airflow and maintaining proper inflation, which directly impacts the safety and functionality of your inflatable. A generic blower might lead to under-inflation or even overheating, both of which pose serious safety concerns. Plus, insurance requirements and local regulations often mandate adherence to the original manufacturer’s specifications.

Another area where OEM parts are non-negotiable is load-bearing seams and reinforcement panels. These are the high-stress zones found on water slides, entrances, exits, landing areas, and anchor points. Since these areas endure heavy impacts – especially on obstacle courses and combo units – using mismatched fabrics or seams from generic parts can compromise the structure, increasing the risk of tears. For equipment used in high-demand rentals, OEM parts ensure the inflatable performs as it was originally designed to.

Additionally, attachment and anchoring hardware such as D-rings, anchor points, and tethers require OEM precision. These components play a crucial role in maintaining wind stability and distributing loads properly. Generic hardware might not align with the tested load paths, creating potential safety hazards. Similarly, zippers and pressure-relief valves, which regulate internal air pressure, must meet exact specifications to avoid problems like over-inflation or sudden deflation during use.

When Generic Parts Are Acceptable

Generic parts can be a good option for cosmetic repairs in areas that don’t bear heavy loads. For example, vinyl patches on side panels, touch-ups for decorative artwork, or replacing banners are low-risk fixes that won’t compromise the inflatable’s structural integrity. These repairs can also help save on costs without sacrificing safety.

Items like storage, cleaning, and accessory components – such as tarps, storage bags, or non-load-bearing straps – are also suitable for generic alternatives. Since these items don’t directly affect the inflatable’s performance during operation, using non-OEM options here is a practical choice.

For concession machines and party add-ons like cotton candy makers, snow cone machines, or event furniture (tables and tents), generic parts are often acceptable. These products typically rely on standardized components, making brand-specific parts less critical. When dealing with older inflatables that are nearing the end of their service life, reputable generic parts can also be a smart way to extend usability without the full expense of OEM replacements. Just ensure that any generic part comes from a trusted aftermarket brand with verified fit and material quality.

Conclusion

Deciding between OEM and generic inflatable parts comes down to aligning the right part with its specific use. For critical components like blowers, structural seams, and anchoring hardware, OEM parts provide the precise fit and dependability that rental businesses need. While they come at a higher cost, they offer the assurance of performance that’s crucial for safety and reliability.

On the other hand, generic parts can be a smart choice for non-critical, cosmetic repairs. They can save up to 50% upfront, but it’s important to weigh the risks – using a subpar part for a key function could lead to costly failures during an event, resulting in repair expenses, lost revenue, and even reputational damage.

Having a clear parts policy is essential for maintaining safety and service quality. For businesses like Bouncy Rentals USA, where customers count on dependable, safe fun, every decision about parts affects the trustworthiness of the brand. A documented policy – outlining when OEM parts are required, when generics are acceptable, and how to ensure quality – helps maintain consistent safety standards and protects both guests and the business.

Ultimately, informed choices matter more than cheap ones. By balancing cost with reliability, rental operators can ensure their inflatables are always ready for action. Prioritizing safety for high-stress components and keeping detailed records of what works allows businesses to confidently deliver fun-filled events, from birthday parties to school carnivals and community gatherings. This thoughtful approach to parts selection helps meet customer expectations and reinforces the promise of a safe and enjoyable experience.

FAQs

Why do OEM parts protect warranties while generic ones might void them?

When it comes to protecting your warranty, OEM (Original Equipment Manufacturer) parts are the way to go. These parts are designed and tested by the manufacturer to meet exacting quality and safety standards. Because of this, they ensure proper compatibility and dependable performance, which manufacturers are willing to back with a warranty.

In contrast, opting for generic parts can be risky. These components aren’t always built to the same precise specifications and may fall short of required safety or quality standards. This mismatch can lead to problems or even damage that the manufacturer won’t cover under the warranty.

What safety standards do OEM inflatable parts follow that generic ones might not?

When it comes to inflatable parts, OEM options are crafted to align with strict safety standards. This includes undergoing extensive durability testing, utilizing high-quality materials, and adhering to industry regulations. These measures ensure that the parts are dependable, built to last, and safe to use.

In contrast, generic parts might not always meet these rigorous standards. This can lead to inconsistencies in performance and potential safety concerns. Opting for OEM parts offers extra reassurance, especially when safety is critical – whether it’s for events or rental purposes.

When should I choose generic inflatable parts instead of OEM parts?

When saving money is the main goal, opting for generic inflatable parts can make sense – especially when the part isn’t crucial to the inflatable’s safety or performance. They’re also a smart pick for components that are simple to replace or widely accessible.

On the other hand, inflatables that endure frequent use or demand greater durability – like commercial-grade bounce houses or water slides – might benefit more from OEM parts, offering better dependability and reassurance.